Category: Good Prints

Standalone 3D printing projects worth writing about.

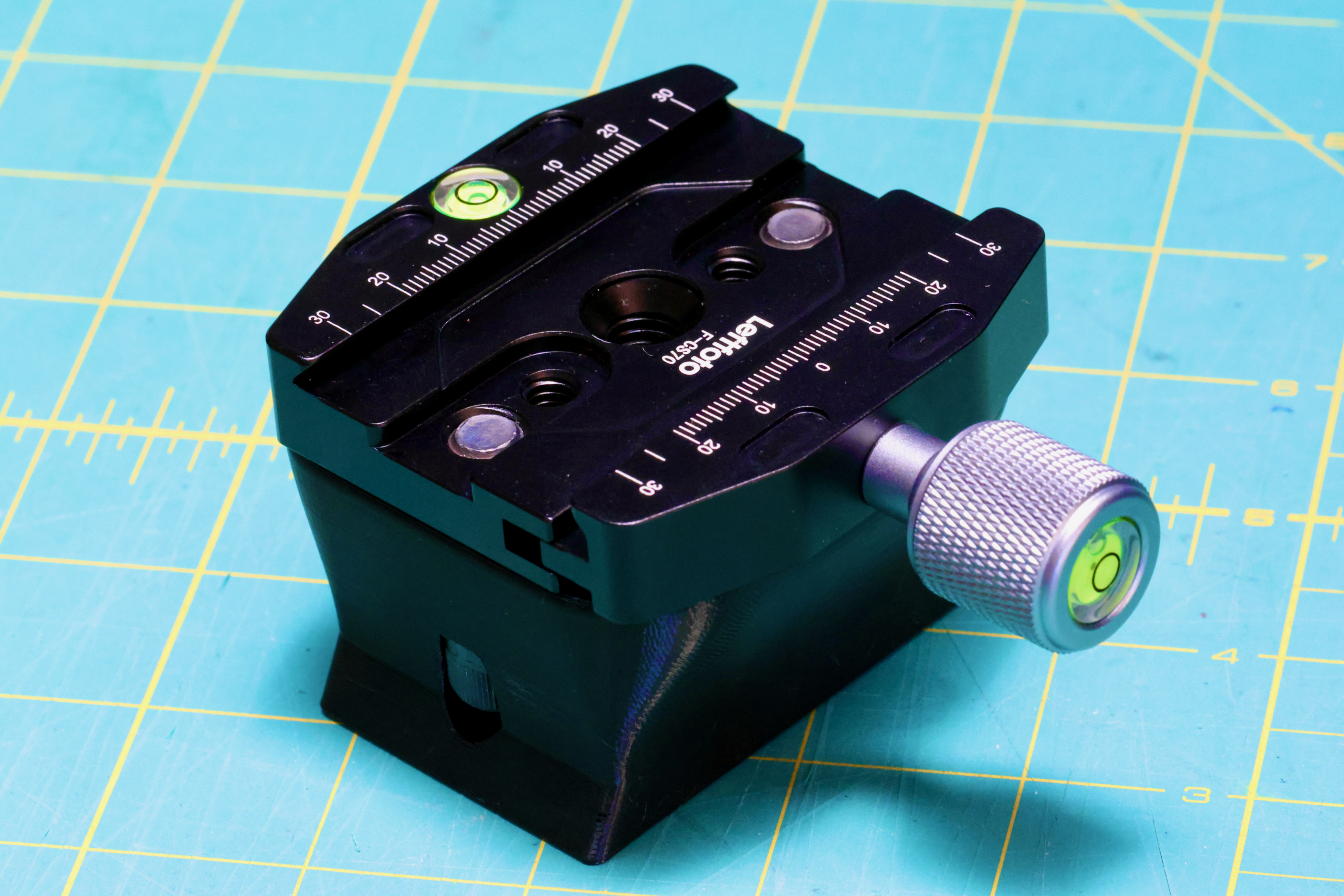

Hardware for Engineering Stream

My beloved blog post still sits on the throne as the most effective format for engineering projects. To me, Inlining code, photographs, CAD models and schematics in an interactive way trumps other mediums. This level of interactivity closes the gap between reader and material, allowing an independent relationship with the subject outside of the story being told by the author.

Working on stream to an online audience has a similar effect, the unedited and interactive format yielding a real understanding of the creators process and technique.

For a while there, I’d settled into a nice habit of broadcasting project development live on twitch. Two moves later, things have settled down enough in my personal life that I feel it’s time to try to get back into this habit.

Before we get started again, I took some time to improve the ergonomics (both hardware and software) of my stream setup. The following documents a few smaller projects, all in service of these upcoming broadcasts.

Stage Pieces for Bensbeendead.

There’s an unspoken tenant of the maker movement that demands: calls for bespoke engineering work from friends should always be answered. Maker projects for friends pay dividends in net-happiness injected into the world.

My ‘ol pal Ben (A.K.A Bensbeendead.) knows this kind of work is a favorite of mine. So when he asked, of course I jumped at the opportunity to design and manufacture some “elbows” that mount his laptop and controller atop RGB stage lighting.

Recycling an Old Friend

This post first appeared on Patreon.

There’s a triple-point energy to working on something out at the edge of your abilities. Enumerated alongside the possibilities for failure are visions of the finished piece, installed and gloriously humming along, that make the long nights ahead less intimidating.

In late October of 2018, I began the CAD for such a project. Telapush had just closed our largest deal to date. We were to contracted to build a massive illuminated sign that would map social media interactions to custom animations to be displayed in real time. The piece was to run, un-attended for the entire month of December in the Center Court of the Prudential Center mall, inside of Boston’s most distinctive skyscraper.

Erin and I had been pouring effort into Telapush for some time, and this installation was to be the largest tangible result from that effort. Serious people spending real money and expecting actual results. Boston was my new home and I felt that this project was my chance to make a good first impression to this new and intimidating place. This heightened importance, paired with the reverence for the challenge, coaxed out some good engineering; the project was a rousing success. More details about this installation can be found in my portfolio entry on the project.

Luckily, one element of the installation that I was able to retain possession of after the installation concluded was the LED matrix. An overwhelming array of 1215 addressable LEDs, and a 100W power supply to drive them.

Still brimming with usefulness, and valuable as a totem commemorating the successful project, the light bar was filed into storage. Unfortunately, I lacked the bandwidth and inspiration to pick it back up. In the past few months however, on quiet nights, I could hear it calling out to me from the crawlspace, pleading to be reanimated. And after a few years of rest, this post describes how this favorite project is given a new lease on life to enhance my 3D printing workflow.

3D Printed Pen + Notebook Organizer

There have been a few posts on this blog about the functional benefits of using printed parts to join existing objects in a reliable and precise way. Most of the time my printed parts themselves look strange. The goals are usually printability and a clean assembly of printed and non-printed. As an attempt to buck this trend, I recently designed and manufactured a desktop organizer that showcases the medium’s ability to bond objects and also look great.

A 3D printed solution for storing a Valve Index on a wire shelf

Looking for a wall mounted version of the HMD mount? Check out this remix on thingiverse (thanks Sean)!

Here’s a video going over the design:

The printed parts can all be found on thingiverse here. Please let me know if you use any of these! I’d love to talk about potential improvements that could be made.

100% 3D Printed Desktop Microphone Stand

Here’s a video:

This is a quick design I came up with rather than spend the $20 on amazon. You can get the STL files on thingiverse here.

Wall-Mounted Drybox for 3D Printing with Nylon

It’s well known that nylon based 3D printer filaments need to be dried out before they’re used. What happens though when you have a 30+ hour print? The spool can take on a lot of moisture in that amount of time and compromise the print.

Many people have solved this problem by making filament dryboxes, somewhat airtight containers that contain a desiccant to dry out the air inside of the chamber.

I have to print several large parts from nylon for client, and I was having trouble in the last hours of the print due to the spool taking on water from the air. I decided to build one of these chambers but with a twist:

Mine is wall mounted! Space in my lab is a premium and the walls are free real estate.

The parts for this build is are available on my Thingiverse page. Oh and if you’re curious, I’m using a wall-outlet-rechargeable desiccant pack from Amazon which I got for $15.

The bolts are M3x10mm, and the nuts are M3 nuts, both from McMaster Carr.

Thanks for reading!

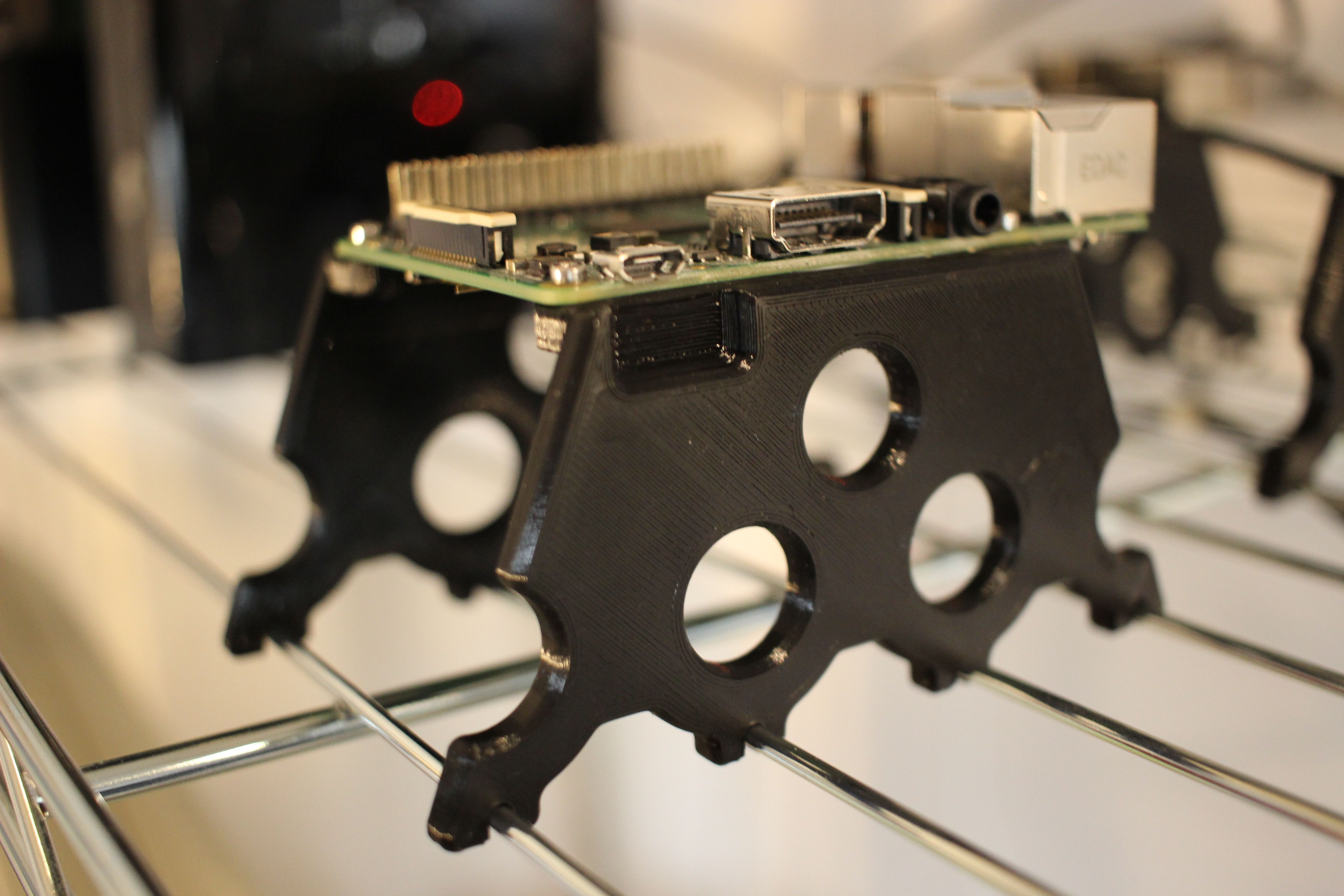

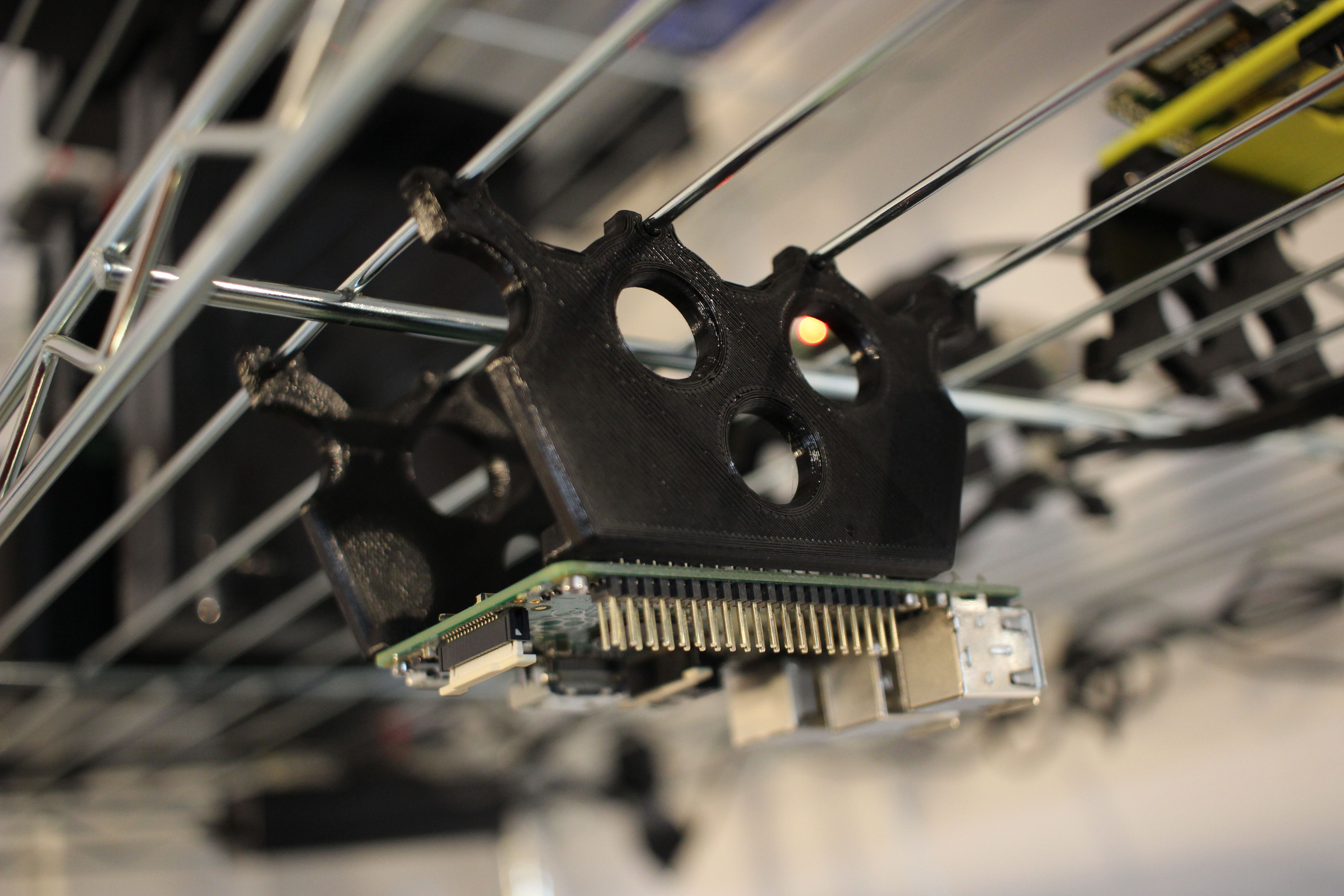

Raspberry Pi Wire Shelf Mount + Wallet & Keys Hold + Spool Hook

Here’s a video:

#goodprints – ep1💥 @Raspberry_Pi shelf mount, Wallet & Keys holder & spool hook #3Dprinting https://t.co/VJzBA0fKx3 https://t.co/zwzWACuzzE

— Devon Bray (@eso_logic) November 6, 2017

For a while I’ve been logging my favorite prints here but some of them are two small to warrant a post. So introducing: #goodprints! At first I’m going to shoot for monthly installments, but as I print more, I’ll post more.

This time we’ve got 3 prints in the above video. Here are the details:

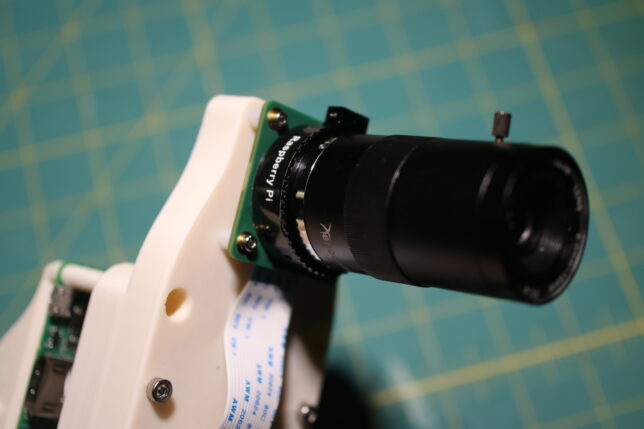

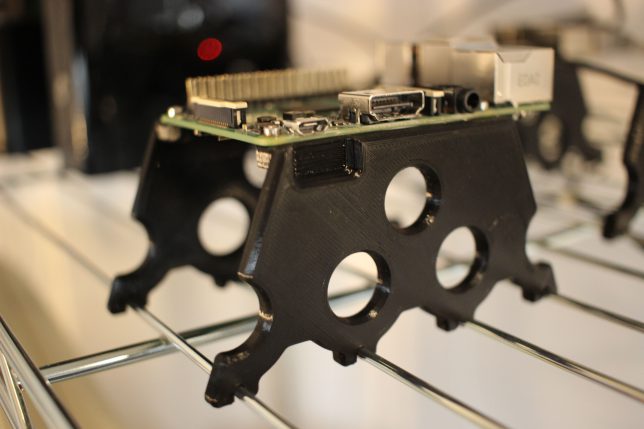

Raspberry Pi Wire Shelf Mount – Everyone knows that wire shelves are the best. Now you can securely mount a Raspberry Pi to one. Thingiverse Link

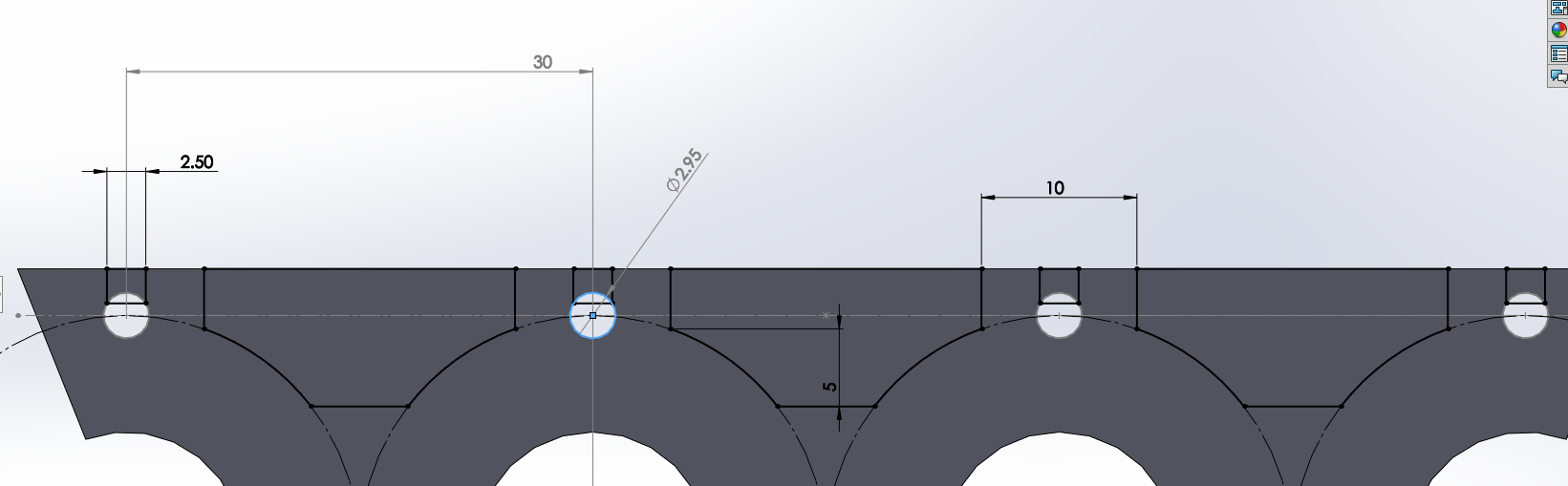

Here is the drawing for mating with the shelf:

Here is the drawing for mating with the shelf:

Wallet, Keys & Leatherman Wall Mount – I’m constantly loosing these things in my lab, now they’re not going anywhere. Thingiverse Link

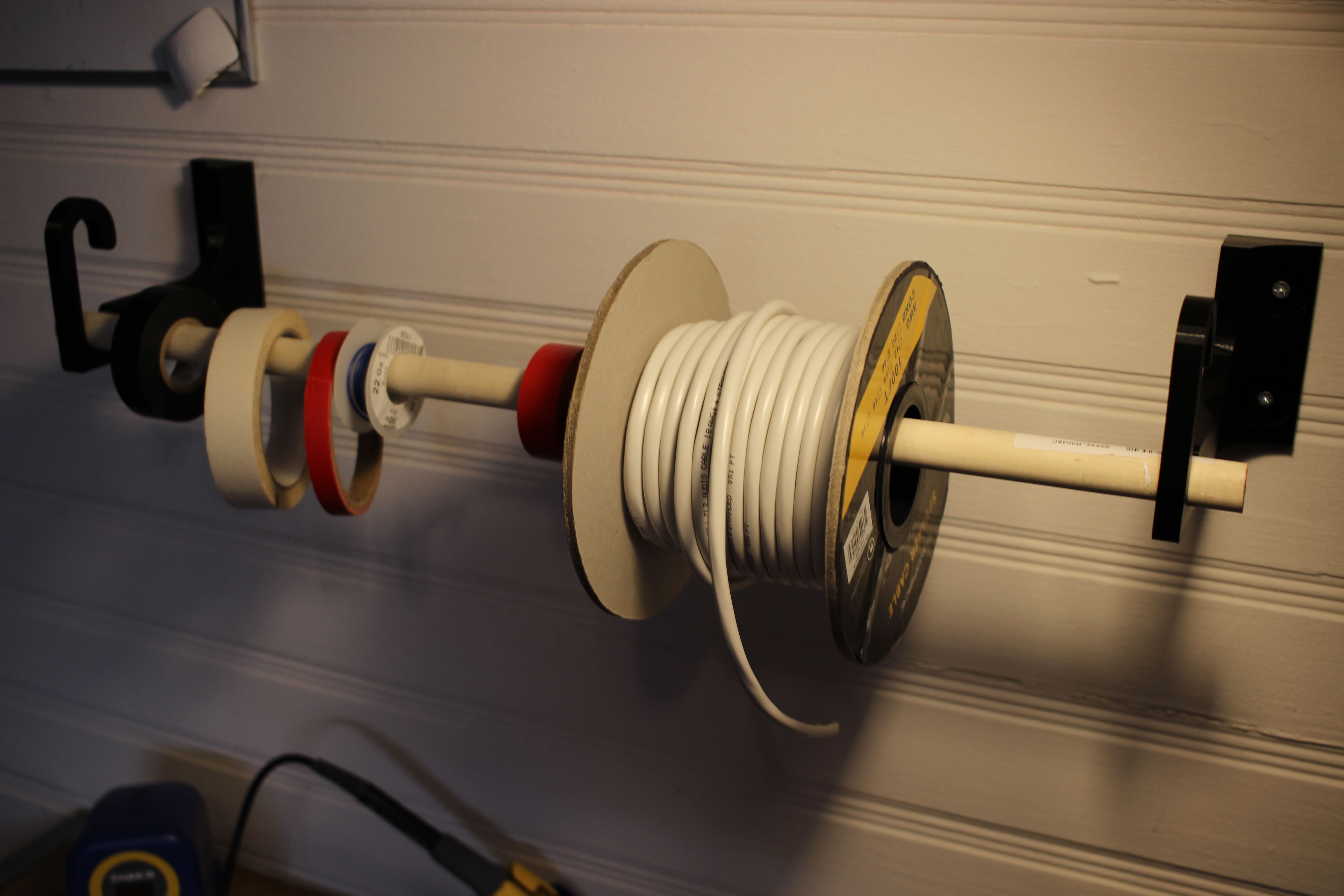

Wall Hook – This is for mounting stuff like filament spools, wire, and tape to the wall. It accepts 3/4 inch dowels. There are two version, one 85mm long and one 150mm long (designed to fit hatchbox 1kg filament spools). Thingiverse Link

Singer Parts Drawer Holder

I use these Akro-Mils 10144 D sets of drawers to keep my various electronics components organized. They’re cheap, reasonable quality, but most importantly inexpensive.

Something that I find myself doing a lot is transferring individual drawers around. For example, I have a specific drawer that holds short jumper wires for breadboards. Sometimes I bring this drawer up to campus for working in the lab. Same goes for my misc-resistor drawer. It’s much easier to move the drawer rather than re-packing it.

The problem is that these are open drawers! They don’t have lids, so what I’ll do is put it in a ziplog bag and throw it into my backpack. This is a bad solution, I have a 3D printer, time to get CADing.

I wanted the drawer to be able to lock in place, so it wouldn’t slide out of the holder while in transit, here is a video of the locking mechanism in action:

As I iterated on this design, it became clear that I could get away with a pretty thin wall thickness, and that extending the slot cut made it much much easier to flex the locking mechanism, so the grab point on the outer surface became unnecessary.

Annoyingly, I couldn’t figure out a good solution to be able to use this part without having to use supports.

If you’re interested, I’m keeping a page of all of my prints. You can find it here.